STRUCTAflor is a range of high-performance structural flooring panels available in three distinct product categories: General Purpose, Termite Treated, and Ultimate.

Backed by over five decades of proven performance and rigorous testing, STRUCTAflor is produced to meet AS/NZS 1860.1. Crafted from responsibly sourced Australian plantation pine, each panel undergoes stringent quality checks and is independently certified by the Engineered Wood Products Association of Australasia.

Celebrating five decades of unwavering commitment to quality and sustainability, STRUCTAflor proudly stands as an Australian Made icon in the realm of structural particleboard flooring.

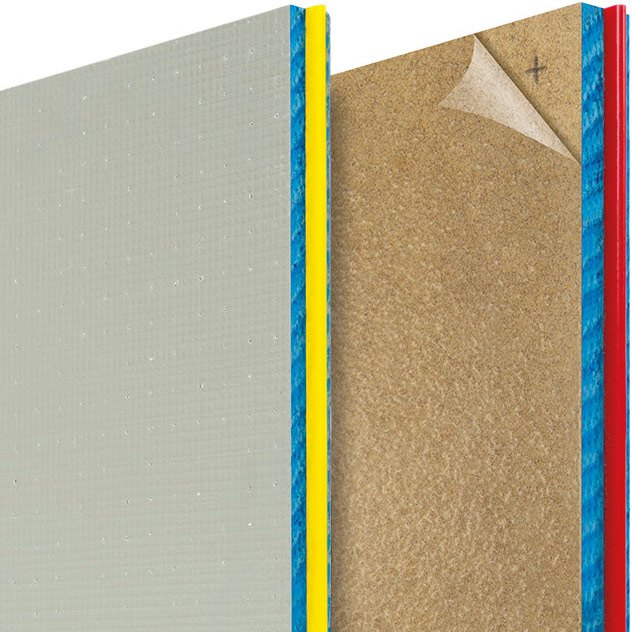

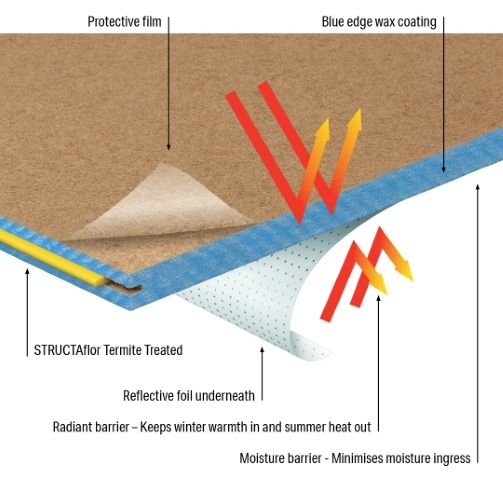

- Resin Enriched Surface for added weather protection during construction for up to 5 months (7 months for Ultimate)

- Hardwearing working surface during installation

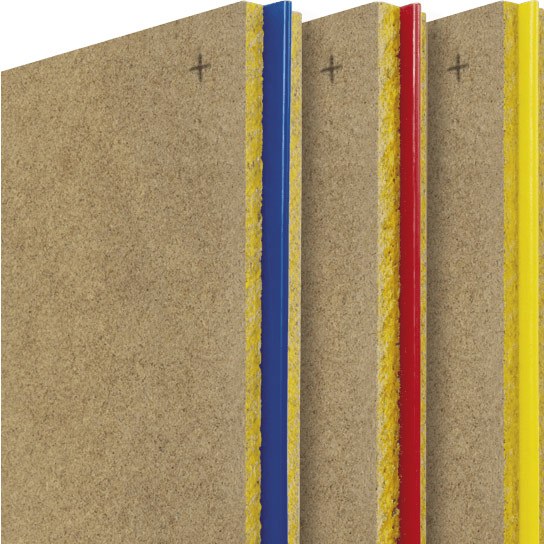

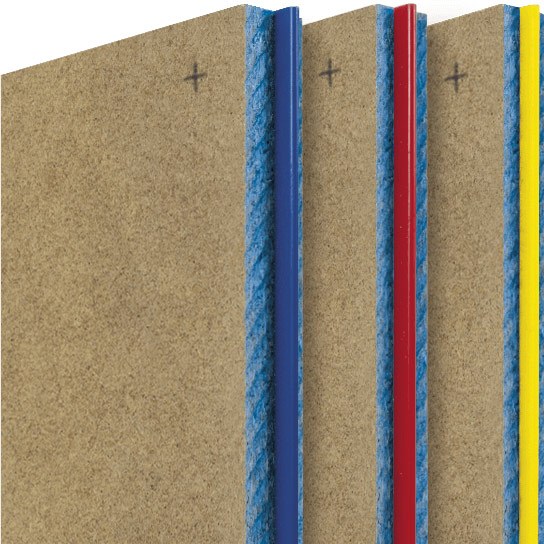

- Edge coating to minimise moisture ingress and easy product identification

- Wax Impregnated throughout for in-built moisture protection

- Fixing pattern marked for quick and easy installation

- Grown from managed and renewable Australian plantation pine